Exceptionally Rare & Fine Morse Altered US Model 1816 Musket - One Of Only 54 Produced

- Product Code: FLA-3840-SOLD

- Availability: Out Of Stock

-

$13,900.00

George Woodward Morse may have been one of the most important firearms inventors of the mid-19th century and left an indelible mark on American firearms development. During his life he received seven US and one British patent related to improvements in firearms and the development of ammunition and he was directly responsible for the first centerfire metallic cartridge breechloading firearm to be utilized by the US military, at a time when percussion ignition muzzleloaders were the standard. He would go on to develop and oversee manufacture one of the most advanced firearms to be used during the American Civil War, a gun that would be made in the Confederate South, and he would sue the United States government after the war, claiming they had infringed upon his patents.

Morse was born in Haverhill, NH in 1812 and would spend most of his early life in New England. His education was limited to primary school, but Morse was mechanically minded and was one of those gifted geniuses who did not need college to bring his ideas to fruition. Sometime between 1829 and 1830 he took work in as a machinist in Quincy Point, MA and the following year went to work for Otis Tufts in Boston. Tufts was a machinist and inventor who produced a wide variety of items from a steam-powered pile driver of his own design to printing presses and carriages for railroad cars. Not long after going to work for Tufts, Morse helped develop a steam-powered printing press with Tufts that would revolutionize printing. Tufts was impressed not only with Morse’s contributions to the project but with Morse’s ability to explain and operate the device. As a result, he sent Morse to England in 1835 with one of the presses to promote it. Morse would spend two years in England demonstrating and promoting the press and would not return to the United States until December 27, 1837. Upon his return, Morse relocated to Louisiana, where his brother Peabody and his two sisters had moved several years earlier. Here Morse would change career paths for slightly more than a decade, serving as the Deputy Surveyor of the Northwestern District of Louisiana from 1842-1852 and becoming the State Engineer of Louisiana in 1852. During this time Morse married a young local widow, acquiring land and slaves that belonged to his new wife. Morse acquired hundreds of acres on his own during this period, as well as additional slaves. By the mid-1850s Morse was fairly wealthy and successful, but apparently felt unfulfilled and his innate mechanical ability and inventiveness pushed him back in that direction.

According, Morse’s own deposition from his post-war suit, he had been fascinated with firearms and the development of a breechloading cartridge firearm for some time, potentially back to when he was a teenager. Maybe the time he spent surveying in Louisiana and helping to reclaim swampland gave him the time to work out concepts and designs in his head, but by the mid-1850s he had produced a wooden patent model, was applying for firearms design patents, and had contracted with a reclusive Baton Rouge area gunsmith named Dane Searles to produce a functional version of the gun. The gun was a breechloading firearm that fired a self-contained metallic cartridge firearm that was centrally primed. Morse received his first two patents, #15995 and #15996 concurrently on October 28, 1856. The first was for his breechloading firearm design and the second, and realistically much more important one, was for the metallic cartridge design. The firearms design was not particularly innovative, other than the use of an integral extractor system built into the breech mechanism. It featured a breech lever that was lifted to open the breech, allowing the use to insert a cartridge. When it was closed the sliding breech block seated the cartridge and it was ready to fire. After firing the “nippers”, as Morse referred to them, pulled the rimmed metallic cartridge out of the breech when the lever was opened. The innovative concept was that Morse achieved his gas seal with the self-contained cartridge. In a world where breechloading firearms designs had been experimented with for at more than a century, the ongoing problem had always been how to effect obduration and create a secure seal that kept gas from escaping from the breech of the gun. Even the most well-known and successful American designs of the period like the Hall and Sharps designs still suffered from gas leakage, as did the revolutionary Prussian Needle Rifle. Morse solved the problem with his soft metal case that expanded when the cartridge was fired, effectively sealing the breech and effecting obduration. His cartridge design was also revolutionary because it was centerfire, rather than rimfire and inherently reloadable. Although he mentioned the design advantage, the reloadability of the cartridge casing was not listed as one of the features that he sought to patent.

As with every firearms designer in America during the mid-19th century, Morse very quickly sought to obtain a US military contract for arms of his design. Morse sought an audience with Secretary of War Jefferson Davis, who was not a huge proponent of the use of breechloaders for the infantry but thought that the concept might have some value for the cavalry. The sample arms that Morse had available were the handmade work of the Louisiana gunsmith Dan Searles, but Morse knew that Searles could not mass produce the guns and so he sought a larger, well established New England gunmaker to help with the project. While simultaneously pursing a military contract, Morse contracted with the Worchester, MA firm of Hitchcock, Muzzy & Co (later simply Muzzy & Co) to produce a sporting version of his gun, based upon his Patent #15995. He arranged for Muzzy to produce one hundred cased three-barrel sets that included a shotgun, rifle, and carbine barrel. The receivers and barrels were threaded to allow the easy exchange of barrels on the single frame.

Meanwhile Morse’s design was tested by the US military at West Point in August 1857 in attempt to select a breechloading carbine for cavalry service. The trials initially included some eighteen different arms designs, but one designer named Sherman withdrew from the trials due to his belief that the Morse design was substantially superior to his own. Since Morse used a self-contained metallic cartridge that was self-primed, the ammunition as substantially better than the patent ammunition used in any of the other designs. Only two designs other than Morse’s used a brass cartridge case and only two other designs were internally primed. His gun was the third fastest shooting, firing 18 rounds in one minute and forty-five seconds. Only the Maynard and Greene designs were faster shooting. Due to his ammunition design, the Morse was inherently waterproof and thus was more reliable in poor weather than any of the others. Despite this, Erskine S. Allin, the Master Armorer at Springfield Arsenal noted that the Morse design was “not suitable for military purposes.” Allin would eventually change his mind in this regard but was clearly not impressed initially. In the end, the testing board selected the Burnside design unanimously. Although the Burnside also used a brass cartridge to load the gun and create the gas seal, it still required the manual addition of an external percussion cap to fire. This made it slower and less reliable than the Morse design.

Despite the setback Morse was undeterred. The new Secretary of War after the resignation of Jefferson Davis was John B Floyd who was much more receptive to the concept of breechloaders in general military service, and not just for the cavalry. Floyd was impressed with Morse’s design and not only ordered further testing of the design but also cancelled the initial Burnside order. It appears that by the next time Morse was able to demonstrate his design in November 1857 he had a new gun made by Muzzy, rather than the earlier Searles produced gun. Morse’s design was tested by both the army and the navy and the navy, in particular, was very impressed with weatherproof design of the Morse cartridge, a very important feature for that branch of service. The reports to Floyd from the testing officers were so positive that Floyd became a strong supporter of the Morse design.

If Morse had a fatal flaw, it was his inability to be satisfied with his designs and had a constant need to improve his work. On June 8, 1858, he received US Patent #20503 which was a new version of his breechloading design. During this period Morse also started to think about how to apply his breechloading design the alteration of muzzleloading muskets. Morse knew that Floyd saw breechloaders as the future of the military but also knew that Floyd did not have the funding to purchase new breechloaders for the entire army. Much like the system of altering flint firearms to percussion that had been undertaken a decade earlier, Morse hoped that maybe he could get a contract to alter percussion muzzleloaders to breechloaders by his system. This had the potential to modernize the military at a much lower cost and also allowed the obsolete arms in inventory to have a longer useful service life. To that end, Morse managed to convince Floyd to order the alteration of some sample arms. On February 28, 1858, Floyd ordered that one percussion altered, rifled and sighted US Model 1816/22 musket be altered by Morse’s system to a breechloading cartridge gun. On March 13, 1858, it was additionally ordered that a smoothbore M1816/22 musket be altered also, as well as a US Model 1841 “Mississippi” Rifle. The first gun altered was fired 1,350 times without a fault or failure and was quite successful. It was additionally estimated that the cost of altering the muzzleloaders to Morse’s system would only cost between $2.50 to $3.50 per gun. The additional guns that were altered were not fired nearly as much, only 425 times for the smoothbore and 74 times for the rifle, and as with the first gun the performed flawlessly.

Eventually, both by convincing Floyd of the economy and expediency of the alteration process and by applying some pressure from within Congress for the funding, Morse finally achieved his goal. Congress appropriated $50,000 for the modernization of the small arms of the US military. Half of the funds were earmarked for the acquisition of newly made breechloaders, the other half was designated for the alteration of existing stores of muzzleloaders to breechloaders and for the investigation of a new priming system, for which $5,000 of the $25,000 was to be used.

Another set of trials was held at West Point in July of 1858. One was for the breechloading carbine design, and the other was for the best breechloading alteration design. Despite Morse suggesting a “simulated rain” test as had been done by the navy and which the Morse design had passed with flying colors, the board still did not pick the Morse design for the carbine. They returned to their original choice from the previous year and selected the Burnside to be purchased with the available $25,000 in funds. The breechloading alteration competition pitted the Morse design against the Joslyn, Mont-Storm, Maynard, Merrill, and Sharps alterations. The tests analyzed the penetrating power, accuracy, speed of firing and overall strength and endurance of the designs. The Morse came in first in terms of penetration but was last in speed of firing due to a large number of failures to fire, the result of faulty ammunition. Despite this setback the board still selected the Morse as the best of the designs tested for alteration but noted that the tests were not really sufficient to make a final decision and recommended field trials with larger number of guns.

Morse in the meantime had continued to work on and improve his designs. On 11 May 1858 he received US Patent #20214 for improvements in ammunition design. The core improvement covered by this patent was the addition of what would be called an “anvil” in modern ammunition. This was a reinforced piece of metal inside the casing that the primer was struck against when the firing pin struck the primer. This is central to the design of nearly all modern centerfire ammunition and is certainly Morse’s greatest contribution to firearms technology. A month and half later, he received US Patent #20727 on June 29, for more ammunition design improvements.

By this time, it appears that Morse may have been running low on personal funds, as he started lobbying to receive a lump sum payment for the use of his patent in the alteration of arms. Eventually Floyd agreed to pay Morse a flat fee of $10,000 to cover the rights to alter 2,000 muskets to breechloaders. This left only $10,000 of the $20,000 that had been allotted for the alteration project. Based upon the estimate of the alteration costs running between $2.50 to $3.50 per gun, that meant that theoretically between 2,857 and 4,000 guns could be altered with the remaining funds. However, the estimates apparently did not consider the cost of tooling up for the work and creating the production line. Nor did it take into account that it had been decided to experiment with the Mont-Storm design at Harpers Ferry as well, with $2,500 to fund this work coming from the same budget.

The work to alter guns to Morse’s design at Springfield Armory was based upon his second firearms patent, #20503. But as the funds were being expended to get a production line up and running and parts were being produced for the alteration process, Morse started to tinker with the design again. Morse brought Washington D.C. gunsmith C.H. Munck in to work with him to modify the design and improve it further. The end result was sort of a combination of features from his initial patent and the second one but threw a wrench into the alteration process. This meant more time wasted, more money spent and that the sample “pre-production” guns that were supposed to be the models for the work were actually different from the “regular production” guns! Research indicates that by the 22nd of February 1858 more than $1,250 had been spent to produce the initial three sample guns and four additional ones, an average of $178 each. This was a far cry from the $2.50 to $3.50 per gun original estimate. After juggling the numbers and revisiting the budget it was decided the alteration of muskets to Morse’s design would be capped at no more than 600 guns, or when the funds ran out. By June 28 of 1859, the funds had been exhausted. This was primarily due to Morse’s constant tinkering with the design and trying to incorporate new modifications.

In all a total of 60 muzzleloading guns were successfully altered to breechloaders by the Morse system between calendar years 1858 and 1859. This included the three sample guns, one each of a smoothbore M1822, a rifled M1822 and a M1841 rifle, two additional sample M1841 rifles (one altered in 1859 and one in 1860) and 54 regular production M1822 rifled muskets. Additionally, there were 540 other M1822 rifled muskets in various stages of alteration that were not completed and were not useable. Other than the sample guns, which were altered with the solid hinged breech block of Morse’s patent #20,503, all of the guns were of the “hybrid” alteration type that was developed by Morse and Munck, and which included features of both Morse’s original patent with the sliding block and the later patent as well. Collectors have noted that of the roughly twenty surviving examples of the Morse altered rifled muskets, that there are some minor variations between the internal parts. This is further indication of Morse’s constant need to try to improve and upgrade his designs. However, his penchant to not leave well enough alone meant that valuable time and monetary resources were wasted which limited the number of guns that were altered at Springfield Arsenal.

Despite what could be called a “failure” in terms of producing the number of altered guns requested, Secretary of War Floyd was still a huge proponent of the Morse concept and through the wrangling of Morse and others, with support from Floyd, Morse managed to receive a contract in early 1860 to produce 1,000 breechloading carbines for the US government. Interestingly, the production was to take place at a national armory, in much the same way that the original Rifle Works had been established at Harpers Ferry as a public-private partnership with John Hall to produce the Hall Patent Rifle. A disagreement regarding the caliber of the new carbines ensued with Admiral Dahlgren of the Navy proposing .69 caliber, some elements of the Ordnance Department preferring .54 caliber and Morse lobbying for .44 caliber. In an attempt to make a determination regarding the preferred caliber, it was ordered that Springfield Arsenal alter four additional Harpers Ferry Model 1841 Rifles to the Morse system, to test the guns in .54 caliber. However, no rifles were available at Springfield, so they had to be ordered to be shipped in from Harpers Ferry. In the meantime, at Morse’s request, the Morse altered M1816/22 Muskets had been sent to Washington Arsenal in hopes that they would be issued for field trials. However, the ammunition for the guns that was to be produced by Muzzy had yet to arrive. In fact, one of the 54 regular production Morse muskets had been sent to Muzzy for use as a test rifle for the ammunition. Another ammunition contract was let to Augustus Brown of Waterbury, CT, which was also delayed and like all of Morse’s projects came in over budget. At about this time, Morse’s old nemesis Jefferson Davis discovered that Floyd had actually paid Morse for the right to use the patent on the altered guns. As a result, Davis sponsored and passed legislation that prohibited the Ordnance Department from using privately held patent designs. It further prohibited paying for the use of, or purchasing the rights to, such patents without authorization from Congress via the passage of a law which would be applicable to that specific patent only.

By July of 1860, it had been ordered that the machinery and equipment that had been used to produce the Morse alterations be removed from Springfield and forwarded to Harpers Ferry to start producing the Morse carbines. Muddled reports and surviving letters suggest that in fact five sample or prototype carbines were produced at Springfield during 1860, along with a set of production tools and gauges. At least one letter from Erskine Allin mentions that the guns had been completed and test fired and that the tooling was being forwarded to Harpers Ferry for production of the guns. It appears that these were the real prototypes for the more famous, South Carolina produced Morse Carbine. Letters indicate that three were made in .44 caliber, two in .50 caliber and that an additional .54 caliber barrel as ordered for testing as well. These five guns were then sent to the Washington Arsenal, likely for further testing. An interesting side note is that famed Texas Ranger and later Confederate General Benjamin McCulloch had had the opportunity to utilize one of the Muzzy-built sample Morse carbines during the Mormon Campaign and had fallen in love with the gun and the design. He managed to obtain the Springfield-made Morse Carbines from the Washington Arsenal in December of 1860 and would carry one as his personal weapon during the Civil War until his death on 7 March 1862, at the Battle of Pea Ridge in Arkansas. Secretary of War Floyd resigned at the end of December of 1860 and received two of the carbines from McCulloch, which he took to Richmond. It is appears that at least one or two of the other guns ended up in Morse’s possession.

The election of Abraham Lincoln and the subsequent secession of southern states started the country down the path to Civil War. While Morse was still actively trying to work with the US Ordnance Department at late as January of 1861 to produce his 1,000 carbines at Harpers Ferry and to continue the alteration of rifles and muskets to his system, by March of 1861 he was appealing to his old nemesis Jefferson Davis for help in the acquisition of the Morse firearms tooling that was now at Harpers Ferry, VA. Morse’s wife, children, lands and financial holdings were in Louisiana and certainly influenced his decision to throw his loyalties to the south. However, it is even more likely that his love for his firearms designs were the stronger influence. With the Morse tooling at the Harpers Ferry Arsenal in Virginia, it was only a matter of time before that facility fell into Confederate hands and Morse knew he needed that equipment to continue producing his guns.

After the capture of Harpers Ferry by Virginia state forces on 17 April 1861, all of the machinery, existing gun parts and various tools for the production of rifles, rifle muskets and Morse’s firearms, were in southern hands. The equipment was soon distributed among the various southern arsenals and manufactories, with much of it being relocated to the Richmond Armory and the Fayetteville Arsenal. Some of the equipment was sent to Nashville for the alteration and repair of muskets and it is likely that the Morse tooling went there as well, as by mid-July of 1861 Morse was the superintendent of that facility. Morse certainly intended to produce his carbines in Nashville, but that apparently never came to pass. In February of 1862, as the fall of Nashville became eminent, the equipment at the Nashville Armory was relocated to Atlanta, GA and then to Greenville, SC. It was in Greenville where Morse eventually ended up as well. There he would oversee the production of slightly more than 1,000 of his more famous .50 caliber brass framed Confederate Morse Carbines for the state of South Carolina. As had been his habit when working for the United States, Morse would continue to tinker with and improve his designs, resulting in three distinct versions of the gun being produced during the roughly two years he worked in at the Greenville State Military Works.

After the war, Morse unsuccessfully sued the United States government, claiming that the production of breechloading firearms, particularly those that were cartridge firing, had infringed upon his patents and that he was due compensation. The rather pompous suit essentially claimed that his designs had inspired the production and use of so many breechloaders by the Union. As would be imagined, Morse lost his suit. He did, however, go one to patent further ammunition designs and would continue to try to work with the US government in the acquisition of military contracts. Morse died in 1888.

Offered here is a VERY FINE condition example of one of the extremely rare Springfield Arsenal altered Morse Breechloading Rifled Muskets. This is one of the standard production guns, produced on the hybrid Morse-Munck design, of which only 54 were produced circa 1858-1859. This example is number 9 and as such is one of the earliest of the guns. The number is found stamped in the wood between the cocking lever and the breech and under the breech block. Although the most authoritative references on the subject The Best Gun in the World by Robert Seigler and The Confederate Morse Carbine Myth vs. Reality by Peter Schiffers both refer to the altered muskets as the US Model 1822 (Model 1816 Type II as a collector designation), this gun is 1839 dated, indicating that it is really a US Model 1828 (or Model 1816 Type III). The gun was originally produced at Springfield in 1839 and is so dated at the tail of the lock, with the usual two-line vertical SPRING / FIELD marking forward of the date. The gun had previously been altered to percussion and alteration mating code H 5 is found stamped on the top of the brass pan remnants and inside the neck of the percussion hammer that was modified to serve as a cocking lever during the Morse alteration. The counterpane of the stock retains two clear and crisp sub-inspection cartouches from the original manufacture of the gun, a script JM in an oval, followed by a script TW in an oval. These are the marks of civilian sub-inspectors Justin Murphy and Thomas Warner, both of whom worked at the Springfield Arsenal inspecting arms produced there and also inspected contract arms. In 1837, Warner was made Master Armorer at Springfield and would retain that position for some five years. The final inspection cartouche of Asahel Hubbard, a script AH in an oval, is also clearly stamped in the wood behind the triggerguard. Hubbard was another civilian employee of the Springfield Arsenal during the period who inspected both arsenal produced and contractor made arms. The gun bears a variety of small, single letter sub-inspection marks throughout on both the wood and many small parts. The initials ML are found stamped under the Morse breechblock and the assembly number 9 is found on the spanner screw under the block that holds the firing pin in place.

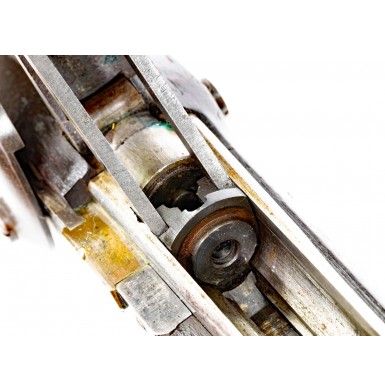

The alteration to the Morse system involved milling away roughly 4” of the top rear of the barrel, forward of the breech plug tang, creating a 3 3/8” opening over the breech area. A hinged breech cover which served as an operating lever was installed at the rear of the barrel, which had a fixed breech block underneath that contained the firing pin. A sliding breech piece, which was secured to the breech cover by two pivoting arms served to seat the cartridge in the chamber when it was closed and to withdraw the casing when the breech was opened. A locking mechanism engaged automatically when the gun was fired and the breech was unlocked to allow it to be opened by pulling back on a pair of checkered wings which also withdrew the firing pin from the base of the cartridge. The nose of the hammer was removed, leaving on the spur to operate as the cocking mechanism, which could also be used to de-cock the gun if so desired. While some sources suggest that the Morse alterations were performed on percussion altered muskets that had already been rifled and sighted, letters from Erskine Allin at Springfield indicate that at least some of the guns were rifled as part of the Morse alteration process. The guns were rifled with the standard Springfield three land and groove system and were equipped with the long-range 1855 pattern rear sight. The original brass blade front sight was left intact on the rear of the upper double-strapped barrel band, and no new front sight was added. One of the advantages that Morse noted for his alteration system during the trials over the competitors was that his system left the stock essentially intact with almost no wood removed. This cannot be said of the alteration systems by Merrill or Joslyn, which involved substantial wood removal and resulted in weak wrists that easily broke. Other than a very small amount of wood removed to inlet the breech hinge, the stocks of the guns were not altered.

As noted, the gun remains in VERY FINE condition and is really a spectacular example of these rare alterations. The gun is essentially untouched and retains some traces of its original arsenal bright polish on the barrel and furniture but has a mostly moderately oxidized brown patina that is thickest on the buttplate and somewhat mottled on the barrel and other furniture. Under the barrel bands the barrel retains nearly all of its untouched bright polish. The lock retains some of its original dull color casehardened coloring and has a dull mottled blue, brown and gray appearance. All markings on the lock remain extremely crisp and clear, as they do in the wood. The Morse breech block retains some strong traces of its original blued finish with a mostly oxidized brown patina on the exterior with some flecks of blue on the top of the lever and on the edges of the checkered locking lugs. The underside of the breech block has a mostly dull blue-black patina with some gray. The metal is quite smooth throughout with, only some scattered flecks of minor roughness here and there, accompanying some patches of surface oxidation. The action remains fully functional and operates as it should, with all mechanical parts working crisply. The bore of the gun is mostly mirror bright with excellent rifling and showing only some scattered areas of light surface oxidation and discoloration, primarily near the muzzle. The gun retains the original 1855 pattern long range rear sight, the original brass front sight blade and both sling swivels. The original button head ramrod is in place, is full-length and has fine threads at the end. The rod has not been dished for use with conical ball ammunition, as it would have been if the gun was upgraded with rifling while it was a percussion musket. As a breechloader, this additional step to modify the ramrod was unnecessary, so it was not performed. This is further indication that the rifling of the Morse guns took place as part of the Morse alteration process. The stock of the gun is in VERY FINE condition as well. It is extremely crisp and retains some feathery texture. The stock is full-length and free of any breaks or repairs. The edges are still very sharp, and the stock shows absolutely no signs of having been sanded. The wood does show some scattered minor bumps, dings, and minor surface mars, but absolutely no abuse or damage.

Overall, this is a really exceptional example of one of the rarest of US military arms. With only 54 of these Morse altered muskets produced and with less than half of those believed to still exist, this is a very rare opportunity to own an incredibly important and historic American military musket. These were the first breechloading firearms to see use by the US military that fired a self-contained, centerfire cartridge. For all of Morse’s bombast and despite the failure of his post-war lawsuit, it is fair to consider him the father of US military breechloading cartridge firearms. It is impossible to look at the Morse design and not feel that Erskine Allin was influenced when he developed the “Trapdoor” alterations for US muskets after the Civil War, and other gun designers were certainly similarly influenced. Morse’s patents for centerfire ammunition paved the way for most of the ammunition produced and in use today, and his influence if felt by millions who do not even know it. For any advanced collector US martial arms, this is one of those extreme rarities that could be a centerpiece of a collection. It would also be equally at home in an advanced collection of Confederate arms, as these alterations were the springboard to the development of Morse’s famous carbine. These very rare guns do not regularly come to market, and this is such a wonderful example that I will certainly enjoy owning it for a while. Few military arms represent the major advance in technology as do these Morse alterations. I am absolutely confident you will be extremely pleased to add this fabulous example to your collection and will always look at it with pride.

SOLD

Tags: Exceptionally, Rare, Fine, Morse, Altered, US, Model, 1816, Musket, One, Of, Only, 54, Produced