Christian Sharps is probably responsible for designing the most successful and recognizable family of breechloading arms of the 19th century. Sharps’ early training in the field of firearms had occurred at the Harpers Ferry Arsenal in Virginia, where he went to work in 1830 under the supervision of gun designer and pioneer of parts interchangeability, John Hall. Sharps worked at Harpers Ferry for over a decade, learning the arms making trade, as well as the early concepts of assembly line production. In 1848 Sharps received his first patent for a breech-loading carbine and moved to the Philadelphia area, where he proceeded to contract with a local gun maker to manufacture his new design. The first Sharps patent firearms were produced by A.S. Nippes of Mill Creek, PA in 1849 and 1850. By 1851, Christian Sharps formed the Sharps Rifle Manufacturing Company in Hartford, CT. As the company was not yet ready to produce arms, Sharps entered into an agreement with Robbins & Lawrence of Windsor, VT to manufacture his arms. By 1852 RS Lawrence (formerly of Robbins & Lawrence) moved to Hartford and became the master armorer of the Sharps Rifle Company, and manufacture of the arms began in house a year or so later. However, Christian Sharps and the others at the Sharps Rifle Company did not always see eye to eye, and in 1853 Sharps left the company that bore his name and returned to the Philadelphia area. Over the next seven years, the Sharps Rifle Company continued to grow, producing a variety of carbines and rifles of various patterns, with each new pattern an attempt to improve upon their earlier designs. Several thousand arms were produced by the company during this time both for various small US government contracts and for sale to the general public. The Sharps Rifle Company really struck gold with the introduction of their “New Model” 1859 series of breechloading percussion carbines and rifles, which they subsequently improved upon with the “New Model” 1863 pattern. During the Civil War, the Sharps Rifle Company produced thousands of carbines and rifles for the US government with more than 77,000 of his carbines being purchased for use by the US military. However, all this success was without the namesake of the company at its helm. Rather, Christian Sharps established a new business under the name C. Sharps & Company in Philadelphia in 1854. The C. Sharps Company initially produced a single shot, breech loading pistol and quickly followed this up with a “pistol rifle” design. In 1859, Sharps received a patent for what would be the most successful design and the biggest money maker for his new venture, a four-barreled pepperbox pistol. Sharps produced the guns in a variety of variations, based upon their caliber, and thus their frame size. The guns were manufactured in .22RF, .30RF and .32RF, and over the next few years Sharps produced thousands of the easily concealable personal protection cartridge guns. In 1862 Sharps entered into a partnership with William Hankins, and for the next four years the firm of Sharps and Hankins concentrated on manufacturing percussion breechloading carbines and rifles for the US army and navy. In 1866, the partnership was ended and Sharps returned to working under the C. Sharps and Company name, continuing to manufacture his 4-shot pepperbox pistols. Sharps remained in business making these handy little guns until 1874, when he passed away and the business was closed.

The Sharps Pepperbox design was an innovative way to manufacture a repeating metallic cartridge handgun without running afoul of the Rollin White patent on the bored through cylinder that Smith & Wesson had an exclusive arrangement to use. Rather than using a single barrel with a rotating cylinder, Sharps used multiple barrels with a rotating firing pin. The Sharps design had a square cross section, with two side-by-side barrels stacked on top of two other side-by-side barrels. While the percussion pepperboxes of pervious decades had utilized rotating barrels, which aligned with the hammer when fired, Sharps design had four fixed barrels that were fired by a rotating firing pin in the single hammer. Each time the hammer was cocked the firing pin rotated one quadrant clockwise to bring it into alignment with the next barrel. The single action pistols had a spur trigger that moved forward in its sheath each time the hammer was cocked. To load the pistols, the hammer was placed on half-cock to defeat the interlock mechanism (a safety feature not present on all the variations) and a button depressed that released the barrels to slide forward on the frame. The empty cartridges could then be removed from the chambers and fresh cartridges inserted. During production, the location and the style of the release changed, but the basic concept never did. Interestingly Sharps’ 1859 patent also included an extractor system that was never incorporated into any of his pepperbox designs. Over the decade and half that Sharps produced his little pistols, some 156,000+ would be manufactured in four basic types. They were the Model 1 in .22RF with about 89,000 produced, the Model 2 in .30RF with about 37,000 produced, the Model 3 made by Sharps & Hankins in .32RF Short with about 15,000 produced and the Model 4 (Bird’s Head or “round butt”) in .32RF Short and Long with another 15,000 produced. Within each model were numerous variations based upon small changes in physical design, markings, latch systems and grip material. Barrel lengths varied with each model, in keeping with the frame size and caliber, with the standard length for the Model 1 being 2.5”, the standard length for the Model 2 and Model 3 being 3” or 3.5” and the standard lengths for the Model 4 being 2.5”, 3” or 3.5”. Of course, as with any Sharps product, custom barrel lengths were available by special order and at extra cost. With the exceptions of the Model 1A and some Model 3 pistols, which had gutta percha grips, varnished wood grips were standard. The majority of the production was finished with blued barrels and silver plated brass frames, with the exceptions of the Model 1D which had an iron frame, as did the Sharps & Hankins Model 3. It is also worth noting that the Sharps & Hankins version had the rotating firing pin mounted in the frame and not on the face of the hammer. Again, custom order finishes and grip materials, as well as engraving, were all available by special order at extra cost. The downside to any manufacturing company being run by the inventor of the item being produced is that the inventors need to constantly improve upon his design usually leads to numerous and costly wastes of time as parts are changed, tooling altered, etc. The fact that the very successful Model 1, with more than 89,000 units manufactured was produced in five variations during 15 years attests to this. With some 60,000 Model 1A pistols produced, Sharps’ constant need to improve things meant that that balance of the production went through four additional variations, even though they only represented a third of the Model 1s total production. The Sharps Pepperbox is one of the most instantly recognizable pistols ever produced, and in addition to the more than 150,000 produced by Sharps, many more thousands were produced around the world, copying Sharps design. Some, like those manufactured by Tipping & Lawden in England or Ghaye of Liege were made under a licensing agreement with Sharps, while others were outright patent infringements and forgeries. The Sharps Pepperbox has honor of being one of the few 19th century firearms designs that is still being produced today, both as reproductions of the mid-1800s gun and as modern variations upon a long-expired patent design.

Offered here is a VERY FINE to NEAR EXCELLENT condition Sharps Model 2A by Tipping & Lawden of Birmingham, England. This is one of those Sharps pepperboxes that was produced under a licensing agreement with a foreign maker. Tipping & Lawden secured an English patent (#207/1859) to protect the Sharps design in that country. The Birmingham based gunmaking firm of Tipping & Lawden was the trade name partnership between Thomas Tipping Lawden and Caleb Lawden, who established themselves as gun, rifle and pistol makers at 40 Constitution Hill in 1837, expanding to 40 & 41 Constitution Hill in 1852. In 1860, the firm added a London location at 18 Buckingham Street. In addition to the usual production of military pattern muskets and rifles (both for military contracts and commercial sale), the company manufactured sporting arms for the general gun trade both in England and abroad. The firm also established itself as a major manufacturer of handguns in Great Britain by the end of the 1850s. Their first major success in that vein was the manufacture of double action percussion revolvers under Willian Harding’s 1858 patents for Deane & Son in London (these were of the “Deane-Harding” pattern). In 1859, the firm procured the rights to manufacture Sharps’ Patent four-barrel pepperbox revolvers under a licensing agreement with C. Sharps & Company of the United States. Tipping & Lawden also secured their own patents during 1861 and 1862 for a breechloading mechanism (in both percussion and pin fire), a dropping barrel breech loader (with John Thomas) and a cane gun. On March 13, 1869 John Thomas, who was employed as a manager at Tipping & Lawden, was granted British Patent 779 / 1869. His patent was a for a cartridge revolver with a simultaneous extraction system. The patent actually covered three variations of the mechanism, but it appears that only the 1st type of action was produced in any quantity. Thomas entered into an agreement with Tipping & Lawden to produce the revolvers of his design, which they did from about 1869 until they were bought out in 1877 by P. Webley & Son. It is interesting to note that the only firearm that Tipping & Lawden produced under patent or licensing protection that Webley continued to manufacture was the Sharps’ patent pepperboxes. This fact clearly attests to the popularity of the design in Great Britain, although Webley only offered the guns for about two years after the acquisition of Tipping & Lawden.

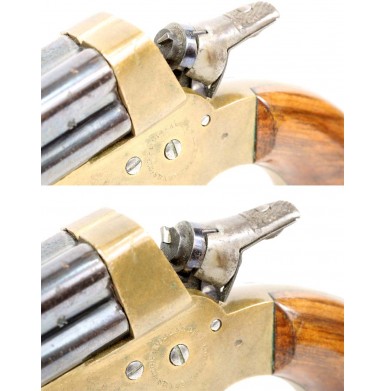

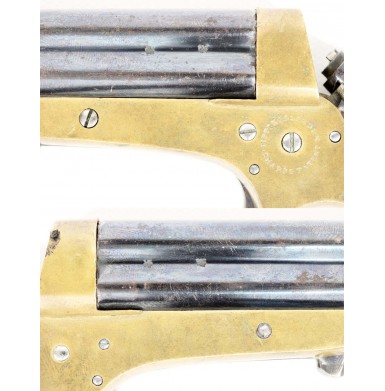

The Model 2A was the first model in the .30 caliber rimfire product line. The standard production Model 2A had a blued 3” long, four-barrel cluster, a silver-plated brass frame and two-piece varnished walnut grips that were squared off where they met the frame, rather than rounded. Other identifying characteristics of the Model 2A were the barrel release at the end of the frame and a flat, rather than fluted (or beveled) area behind the standing breech of the brass frame. The standard markings for the English produced pistols were TIPPING & LAWDEN / SHARPS PATENT in a circle around the hammer screw on the left side of the frame. The only other external markings were Birmingham commercial proof marks on the barrels and a serial number the bottom of the barrel, near the muzzle. This example is serial numbered 5725. All of the markings on the pistol remain crisp, with the circular frame mark being quite clear. The pistol retains about 80%+ of its original bright blue on the barrel cluster, with some fading, thinning and slivering along the high edges from handling and wear. The barrels are mostly smooth with some scattered flecks of surface oxidation and some pinpricking around the muzzles. The brass frame retains none of the silver plating. The brass has a really attractive, rich, butterscotch patina. The right side of the rear of the standing breech shows a small casting flaw. The hammer and firing pin both retain much of their finish as well, with the hammer showing much of the original, vivid case coloring. The rotating firing pin functions exactly as it should, rotating each time the hammer is cocked. The breech locking system works correctly, as does the interlock that requires the hammer to be placed on half-cock in order for the barrels to be released to move forward. The locking system remains very tight with an extremely stiff spring. This requires some effort in order to release the barrels and slide them forward for loading and unloading. The bores remain in FINE condition, with only some lightly scattered pinpricking along their lengths, typical of rimfire arms from that period, as the caustic priming compound could cause major erosion very quickly. The grips are in FINE condition as well, and retain most of their original varnish. They remain very crisp with sharp edges, and no breaks, cracks or repairs. There is some minor wear and finish loss along the lower flared edges of the grips. The grips show only some light handling marks and minor mars.

Overall this is an extremely crisp little Tipping & Lawden Sharps Model 2A Pepperbox. The gun retains most of its original finish on the barrels and hammer and has a really appealing appearance. This would be a wonderful addition to any collection of Sharps handguns, representing an English made variant, or a collection of mid-19th century cartridge handguns.

SOLD