Fine 1822 Dated Robert Johnson Contract US Model 1817 "Common Rifle" In Original Flint

- Product Code: FLA-B128

- Availability: In Stock

-

$4,250.00

The US Model 1817 Common Rifle was a unique US military long arm in that it was never produced at a National Armory, other than some sample models that were made up at Harpers Ferry, with all of its production being handle by contractors. 38,267 of the rifles were produced by five different contractors between 1819 and 1845. The contractors included Henry Deringer of Philadelphia, as well as Robert Johnson, Robert & J.D. Johnson, Simeon North, and Nathan Starr & Sons, the last four all being located in Middletown, CT. Deliveries by the contractors from greatest to least were as follows: Henry Deringer: 13,000, Nathan Starr: 10,000, Simeon North: 7,205, Robert Johnson: 5,002 and Robert & J.D. Johnson: 3,060. Although the rifles were officially adopted in 1817, it appears that in some cases the US Ordnance Department thought of the rifle as the “Model 1819”. The 1841 Ordnance Manual refers to them as “Common Rifle, Full-Stocked; 1819”, which apparently refers to the first year the rifles were delivered. However, most other period sources do use the model designation “Model 1817”.

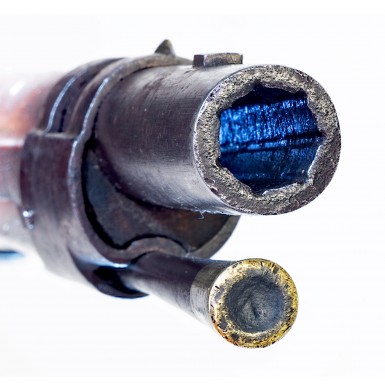

The US Model 1817 “Common” Rifle was an elegant and graceful flintlock rifle. It had a 36” long, .54 caliber, round barrel, rifled with seven deep grooves with a high rate of twist for shooting a patched round ball. The barrel was secured to the stock by three flat barrel bands and a single tang screw. Initially the barrels and furniture of some of the contract rifles was polished to National Armory Bright and were left unfinished. Later the metal of most of the rifles was finished with a lacquer brown. This change over appears to have happened during fiscal year 1826, meaning that those guns that had been left bright by their manufacturers initially were being browned after July 1 of 1825, when fiscal year 1826 began. This changeover can be documented by additional payments made to some of the contractors for browning the rifles. Whether the guns were delivered browned or bright, the lock was color casehardened, and the hammer and small work (screws, small lock parts, springs, etc.) were blued as part of the heat drawing process. The rifle had an oval patch box inlet into the obverse buttstock for the storage of cleaning implements and greased patches. As originally produced, the rear tang of the triggerguard extended to form a skeletonized pistol grip, from which a sling swivel was suspended. Later production rifles eliminated the extended finger-rest tang and relocated the lower swivel to the more conventional location at the front of the triggerguard’s bow. The upper swivel was mounted on a stud below the middle barrel band. The rifle was produced with a fixed, V-notch rear sight and a front sight that was either a brass blade on the upper barrel band or a fixed blade on the barrel near the muzzle. As originally produced, the rifle did not accept a bayonet of any kind. However, examples that have period socket bayonet studs on the top and occasionally the bottoms of the barrels indicated that some were equipped to accept socket bayonets. Later in the months leading up to the American Civil War, and during the early months of that war, many of the percussion altered Common Rifles still in service were modified to accept saber bayonets. The ramrod was a trumpet shaped iron rod with a brass tip to prevent damage to the rifling during the ramming process. The opposite end of the rammer was threaded for the attachment of implements, including a wiper, and ball puller.

The US Model 1817 Common Rifle was extremely popular during its period of use, and many of the guns were delivered to the various states under the terms of the Militia Act of 1808. The rifle saw significant use during the Seminole Wars in the south and during the Mexican American War as well. The rifles continued to serve well into the percussion age, and the National Armories, at the request of the states, altered many of these guns to percussion. The term Common Rifle was a period appellation and was used to differentiate between the “common” muzzleloading rifle and the “less common” and certainly more unique Hall’s Patent breech loading rifle. With just over 38,000 of the rifles being produced by all of the contractors, the guns are far from “common” in the greater scheme of things, when you consider that approximately 900,000 US Model 1816/22/28 flintlock muskets were produced during the same time frame by the National Armories and about two dozen contractors. That production ratio indicates that roughly two-dozen US Model 1816 muskets were produced for every Model 1817 rifle!

With the coming of the American Civil War, thousands of US Model 1817 rifles (many already altered to percussion) were in state armories around the country. Thousands were in the hands of the Southern states that had seceded, but many were in Northern armories as well. Extant examples exist with Seminole War era state ownership markings of both North and South Carolina, as well as the state of New Jersey. Another 5,000 US Model 1817 Rifles were in storage at the Benicia Arsenal in San Francisco in 1861, and many of these rifles were issued to the 1st California Volunteer Cavalry, who fought in the far western theater against Confederate forces in New Mexico and Arizona. Even as late as March of 1863, “Common Rifles” were showing up in Confederate arsenal inventories. With the significant number of Model 1817 rifles altered to percussion during the 1850s and during the early Civil War years, finding a rifle in its original flintlock configuration is very difficult. As such, these guns demand a significant premium when found in original flint condition.

The US Model 1817 Common Rifle offered here is one of the 5,002 guns produced Robert Johnson, and as such was part of the second smallest Model 1817 rifle contract, only the contract with Robert & John D Johnson was smaller, delivering 3,060 rifles. Robert Johnson has been a contractor to the US Ordnance Department since the 1814 rifle contracts the firm received the first contract for US Model 1817 Rifles on March 9, 1819. The contract was for 5,000 arms and the firm delivered 1,100 rifles that year, 1,160 in 1820, 1,340 in 1821, 842 in 1822 and 560 in 1823. This totals 5,002 rifles and the two extra rifles delivered under the contract were sent to Nathan Starr on 1 May 1823 to use as sample rifles for Starr’s contract. The fact that the Ordnance Department was willing to use Johnson’s rifles as samples for another contractor was an indicator of the quality of the work of the Robert Johnson manufactory. Johnson had first contracted with the US Ordnance Department to deliver US Model 1814 Rifles, the predecessor of the Model 1817 Rifle and in another business venture with his brother John D Johnson, the firm of R & J.D. Johnson would also be a US Ordnance Department contractor. Interestingly, Robert also continued to operate on his own account and under his own name as well, and in some cases, it appears that the records regarding the work of Robert Johnson and R&JD Johnson were sometimes intermingled, or researchers have made assumptions about which “Johnson” firm is being referred to in period records. Some of those record irregularities appear to have made their way into the historical record as related this particular rifle.

This Robert Johnson produced Model 1817 Rifle is in about FINE condition overall, and retains some of its original lacquer browned finish, possibly as much as 20%-25% overall, with the patch box retaining the largest amount of this finish. This is somewhat interesting, as a footnote regarding 1817 Common Rifle contracts in George Moller’s US Military Shoulder Arms Volume II notes that “Robert Johnson did not receive extra payment for browning the rifles he delivered, and existing examples indicate they were finished bright.” This rifle, however, clearly retains some of the original brown applied by the manufacturer. Another footnote on the same page regarding the contracts notes that “There is no mention of extra payment to Deringer for the browning of any of the rifles he delivered. Because almost all known examples appear to have been originally browned, it is possible that this was included in the price of the rifles.” The initial Deringer contract was dated 23 July 1819, more than three months AFTER the initial Johnson contract. Since Johnson contract rifles are significantly less common than Deringer contract rifles and were the earliest deliveries, the Johnson rifles likely saw heavy use during the 1820s and are less likely to retain finish on their metal. Deringer delivered only 1,800 rifles between 1819 and 1821 (exact numbers for each year are not known), while Johnson delivered twice as many during that period, totaling 3,600. As both contractors were makers of the US Model 1814 Rifle, which preceded the Model 1817, and since US Model 1814 Rifles were browned, it seems reasonable to believe that both makers browned their initial 1817 contract rifles as matter of course. Later contracts specified bright finish and when the specification was changed, many makers charged an additional fee to cover the cost of browning the guns.

This crisp rifle remains in its original flintlock configuration and is a very attractive example of a rifle that clearly saw a moderate amount of use, but which was never abused. The lock of the rifle is marked clearly, forward of the hammer in an arch R JOHNSON over a {Spread-Winged American Eagle} which is flanked by the letters U and S which is over an arched MIDDN CONN. The tail of the lock is dated 1822 horizontally. As noted, the lock remains in original flint and on the interior shows the matching mating number 4 on the interior of the brass pan, the sear, the bridle and inside of the neck of the cock.

The lock retains traces of bluish brown mottling from its casehardened finish with a moderately oxidized smoky patina and shows some pinpricking and minor pitting along with some scattered minor surface oxidation and age discoloration. The brass flash pan has been lightly cleaned at some point in time and now has a medium golden patina and shows some erosion, debris and staining on its interior. The barrel is clearly marked at the breech with a US / P / N in a horizonal line from the breech towards the muzzle as well as with a V, an X, and a smaller L. The counterpane of the stock is stamped with the deep script LS cartouche of Luther Sage, a Springfield Arsenal civilian ordnance sub-inspector. According to Daum & Pate’s U.S. Military Arms Inspector Marks, Sage inspected US Model 1817 rifles at “R&JD Johnson” in 1819, 1820, 1821 and 1823, with 1,060 inspected in 1822. This is an example of the muddle period records that researchers have to contend with, as R & JD Johnson did not have any contracts for Model 1817 rifles until 10 December 1823. Thus, all of the rifles referenced in the book were produced by Robert Johnson, not Robert & John D Johnson. Sage inspected 2,960 of the 5,002 rifles that Robert Johnson delivered. The number of rifles that Sage inspected in 1822 exceeds the number of rifles that he delivered that year, 1,060 vs 842, which suggests the difference may have actually been received by the Ordnance Department in a different Fiscal Year (deliveries made on or after 1 July 1822 would have been credited to 1823’s fiscal year). A crisp block JJB is stamped in the toe line of the stock behind the triggerguard tang. This is the mark of an unknown inspector.

As noted, the barrel retains some nice traces of its original lacquer browned finish, with moderate amounts of thinning and loss. The markings on the barrel remain crisp and clear. The shows moderate amounts of scattered surface oxidation and some flaky roughness with the brown oxidation blending with the remnants of the brown finish, giving the barrel the appearance of retaining more brown than it really does. There is some moderate pitting around the breech area of the rifle with moderate roughness in this location. The touchhole shows moderate erosion and pitting but is correctly located in the pan, retains the correct tapered and angled profile, and shows no indications of having been molested. The furniture retains somewhat more of the browned finish than the barrel with the oval iron patchbox retaining the largest amount of finish. The buttplate, triggerguard, barrel bands and sideplate all retain at least some original brown with moderate amounts of thinning, wear, and loss. The bore of the rifle in in its original .54 caliber configuration and is in about VERY GOOD condition. It is dark and heavily oxidized with strong rifling but with moderate amounts of pitting scattered along its length. The lock of the rifle is in excellent mechanical condition and functions crisply on all positions. The rifle retains its original V-notch rear sight, as well at its original brass blade front sight on the front strap of the upper barrel band. The rifle also has a rarely encountered feature, a stud for mounting an angular (socket) bayonet on the top of the barrel, near the muzzle. The stud is located nominally 1 ¼” from the muzzle and measures .22” wide and .36” long. The muzzle of the rifle measures .825” in diameter, suggesting that the rifle was designed to accept a standard US Model 1816/22/27 type socket bayonet, which has muzzle diameter of nominally .830. Both of the original sling swivels are present, the lower one attached to the rear of the extended pistol grip at the tail of triggerguard and the upper swivel located on the middle band. The original trumped head, brass-tipped 36” ramrod is present with the rifle as well and retains its original threads at the end. The exposed steel portion of the rod’s shank is lightly oxidized with some scattered discoloration. The stock of the rifle is in about FINE condition as well. The stock remains solid and full-length, and is free of any breaks, cracks, or repairs. The stock shows some scattered bumps, dings and handling marks from issue and use. The stock shows no indication of having been sanded and retains crisp lines and sharp edges throughout. It even retains some feathery texture on the butt, further indicating that it has not been sanded. There are a couple of tiny surface finish chips around the lock mortise, but even that area remains so crisp that a small V inspection mark is still present and fully visible at the rear of the mortise.

Overall, this is a really very nice example of an early production US Model 1817 Common Rifle from one of the smaller contracts for that model. The rifle remains in its original flint configuration and retains some nice remnants of its lacquer browned finish. The rifle was made as part of the second smallest contract for these guns, with only 5,002 being produced, which represents only about 13% of all Model 1817 Common Rifles manufactured. These rifles are rarely encountered in original flint and rarely with any original brown finish. The gun shows a moderate amount of real-world use, but it remains complete and original throughout. This is a great chance to add a fairly scarce and very nice example of a US Model 1817 Common Rifle to your collection, in a very nice state of preservation.

Tags: Fine, 1822, Dated, Robert, Johnson, Contract, US, Model, 1817, Common, Rifle, In, Original, Flint